WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

Zirconia ceramic is a special high-tech material, and its toughening is mainly achieved by the phase change of zirconia ceramics.

Zirconia ceramic is a special high-tech material, and its toughening is mainly achieved by the phase change of zirconia ceramics.

By toughening zirconia ceramics, its products are mainly used for the industries that request a high fire resistance.

Pure zirconia ceramics are white solids and will appear gray or yellowish when they contain impurities. Zirconia ceramics can also show a variety of other colors when adding chromogenic agents.

The molecular weight of zirconia ceramics is 123.22, the theoretical density is 5.89g / cm3, and the melting point is 2715℃.

It usually contains a small amount of hafnium oxide, which is difficult to separate, but it has no obvious effect on the properties of zirconia ceramics.

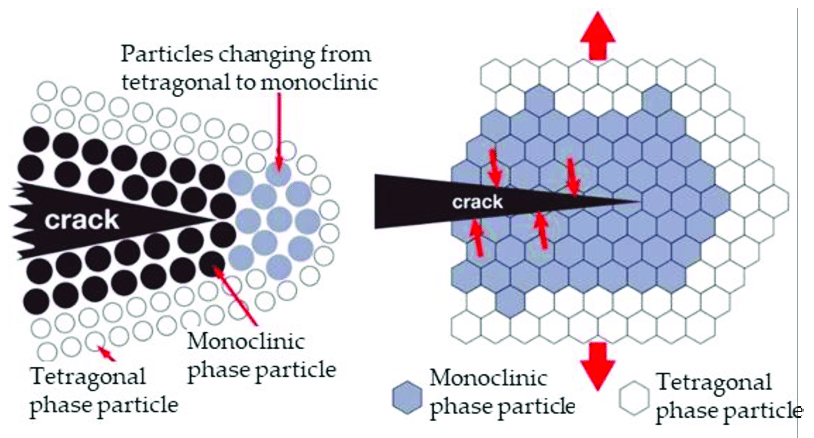

Zirconia ceramics have three crystal forms: monoclinic, tetragonal, and cubic phase.

At room temperature, zirconia ceramics only appear as a monoclinic phase, which is transformed into a tetragonal phase when heated to about 1100 ℃, and to the cubic phase when heated to a higher temperature.

Due to the large volume change from monoclinic phase to tetragonal phase and the opposite direction during cooling, it is easy to cause the cracking of zirconia ceramic products, which limits the application of pure zirconia ceramics in the field of high temperature.

However, after adding a stabilizer, the tetragonal phase can be stable at room temperature, so the volume change will not occur after heating, which greatly expands the application range of zirconia ceramics.

If this article helps you, please follow us on our Official Facebook we just created, we will publish these technical articles there as well.