WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

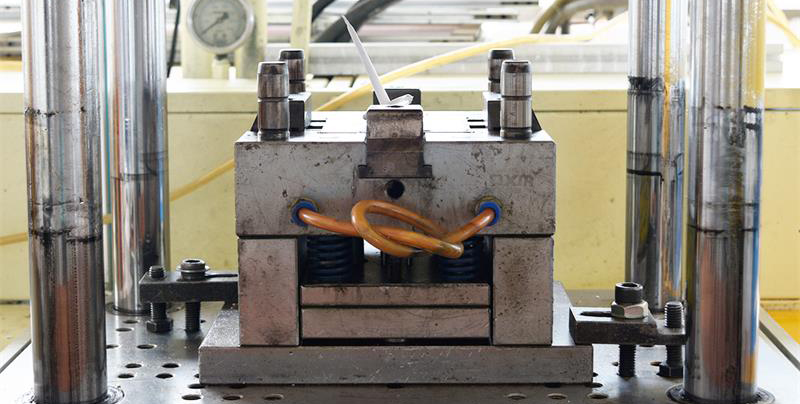

Zirconia ceramic injection molding, also known as hot pressing injection molding, it has been widely used in the manufacture of special ceramic products with complex shape and high requirements for size and quality.

Zirconia ceramic injection molding, also known as hot pressing injection molding, its process is to fill the molten waxy slurry into the metal mold under pressure, remove the film after cooling to get the billet, and then dewaxing and sintering.

The products produced by this method have the advantages of accurate size, high finish and compact structure, and have been widely used in the manufacture of special ceramic products with complex shape and high requirements for size and quality, such as zirconia ceramic structural parts.

Zirconia ceramic injection molding machine can be divided into two types: plunger type and screw type.

Paraffin is commonly used as the plasticizer in the injection molding of zirconia ceramics. It has the following advantages:

1. The melting point is low, the forming can be carried out at 70 ℃ to 80 ℃, and it is easy to operate.

2. After melting, the paraffin wax has low viscosity, easy to fill the mold cavity, and has lubricity, does not wear the mold, and the billet will have a certain strength after cooling.

3. After cooling, the paraffin wax shrinks by 7% to 8%, so it is easy to dewaxing.

4. Generally do not react with powder.

5. The source is abundant and the price is low.

Zirconia ceramics often use oleic acid [CH2 (CH2) 7CH=CH (CH2) 7COOH], zirconia ceramic stearic acid [CH3 (CH2) COOH], zirconia ceramic beeswax as surface-active materials. Because the surface of zirconia ceramic powder is generally charged, polar and hydrophilic, while paraffin wax is non-polar and hydrophobic.

In this way, zirconia ceramic powder and paraffin are not easy to adsorb, and long-term heating is easy to produce precipitation. On the one hand, the surfactant has a hydrophilic group (carboxyl COOH) and ceramic powder is easy to adsorb; on the other hand, it has a lipophilic group, which can be adsorbed with paraffin. Through the bridge action of surfactant, ceramics and paraffin are adsorbed together indirectly.

The preparation of zirconia ceramic injection molding slurry is very important, and the selection and coordination of additives is a highly empirical process research work.

Mingrui Ceramic experienced in the injection molding of the zirconia ceramic parts, we have advanced equipment and a mature technology, if you have any question, contact us!