WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

Industrial valves are a widely used product. Ceramic valves are widely used to replace metal valves due to their excellent temperature resistance, wear resistance, acid and alkali resistance. So if you want to use ceramics to make industrial valves, which ceramic material is more suitable?

With the advancement of technology, more and more types of ceramic materials are used, but our common ones are mainly alumina ceramics, zirconia ceramics, and silicon nitride ceramics.

Ceramic materials are a class of inorganic non-metallic materials made of natural or synthetic compounds through forming and high-temperature sintering. It has the advantages of high melting point, high hardness, high wear resistance, and oxidation resistance. It can be used as a structural part and as a functional material.

Industrial valves are a widely used product. Ceramic valves are widely used to replace metal valves due to their excellent temperature resistance, wear resistance, acid and alkali resistance. So if you want to use ceramics to make industrial valves, which ceramic material is more suitable?

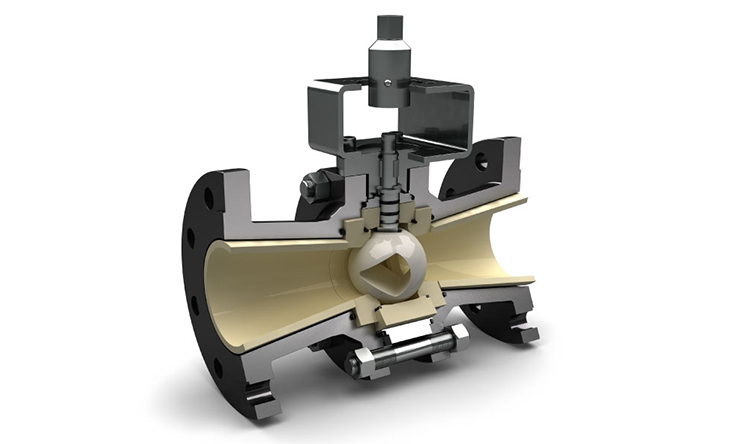

Ceramic valve is a kind of valve used in electric power, petroleum, chemical industry, metallurgy, mining, sewage treatment, and other industrial fields. It has the characteristics of wear resistance, corrosion resistance, high temperature, high pressure, and other harsh working conditions.

Ceramic valves can meet the high wear and strong corrosion environment, especially the outstanding feature is the long service life, the cost performance of ceramic valves is far better than other similar metal valves.

With the continuous development and progress of science and technology, ceramic materials have become more mature and complete in terms of formulation, molding, processing, and assembly technology. Ceramic valves are increasingly recognized by the valve industry due to their excellent performance.

Among the several ceramic materials mentioned above, the properties are different. Alumina ceramics is one of the relatively low-cost materials, and it has good high-temperature resistance, so it is still more popular with users. But its flexural strength is relatively low, which limits its application to a certain extent.

Zirconia ceramics make up for the deficiencies of alumina ceramics in terms of bending strength. Among these materials, it is a ceramic material with good mechanical properties at room temperature. Many valves, such as ball valves, valve seats, butterfly valves, valve plates, etc., are made of zirconia ceramics.

Let’s talk about silicon nitride ceramics. It has the advantages of other materials and also has outstanding high-temperature resistance. Although silicon nitride is also an ideal ceramic material in terms of performance, its large-scale use is affected by its high cost.

In conclusion, alumina ceramic and zirconia ceramic are suitable for making industrial ceramic valves due to their excellent physical and chemical properties and they are cost-effective.

Mingrui Ceramic is a specialist of ceramic valves and valve components OEM, contact us today for getting a free quote!