WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

At present, the commonly used alumina ceramics in the market are divided into two types: high purity type and ordinary type, corresponding to different application fields.

At present, the commonly used alumina ceramics in the market are divided into two types: high purity type and ordinary type, corresponding to different application fields.

What is the difference between these two kinds of alumina ceramics? Let us introduce it to you one by one.

1. High purity alumina ceramics

High purity alumina ceramics refer to ceramic materials with a purity of more than 99.9% of Al2O3. Because their sintering temperature is as high as 1650mur1990 ℃ and the transmission wavelength is 1 ~ 6 μm, they are generally made into molten glass to replace platinum crucibles.

In addition, because of its light transmittance and alkali metal corrosion resistance, it can also be used as a sodium lamp. It can also be used as an integrated circuit substrate and high-frequency insulating material in the electronic industry.

2. Common alumina ceramics

According to the purity of Al2O3, common alumina ceramics are divided into 99% alumina ceramics, 95% alumina ceramics, 90% alumina ceramics, 85% alumina ceramics, and other varieties. Sometimes the Al2O3 purity of 80% or 75% is also classified as ordinary alumina ceramic series.

| Performance | index |

|---|---|

| Alumina ceramic purity | ≥ 92% |

| Density | ≥ 3.6g/cm3 |

| Rockwell hardness | ≥ 80 HRA |

| Compressive strength | ≥ 850Mpa |

| Fracture toughness KIC | ≥ 4.8MPa ·M1 / 2 |

| Bending strength | ≥ 290MPa |

| Thermal conductivity | 20W/m.K |

| Coefficient of thermal expansion | 7.2 × 10-6m/m.K |

99% alumina ceramics is used to produce high-temperature crucibles, refractory tubes, and special wear-resistant materials, such as ceramic bearings, ceramic seals, and water valves.

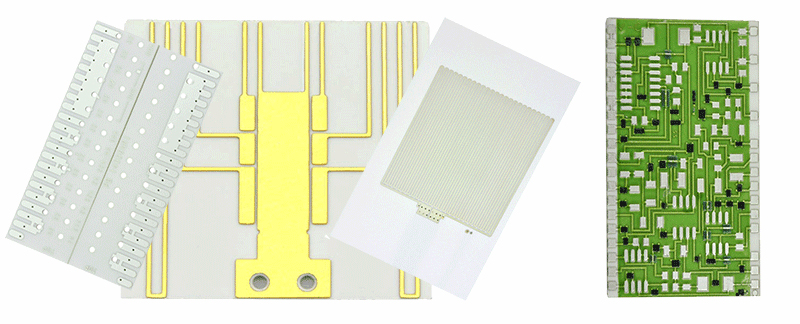

95% alumina ceramics is mainly used as corrosion-resistant and wear-resistant parts.

85% alumina ceramics is often mixed with talc, which improves the electrical properties and mechanical strength, and can be sealed with molybdenum, niobium, tantalum, and other metals, and some can be used as electric vacuum devices. But the general alumina precision ceramic parts are made of alumina ceramic materials with a purity of more than 95%.

Mingrui Ceramic specialized in the custom manufacturing of purity 95% ~ 99.99% high precision alumina ceramic parts with high performance and low torelance, contact us if anything we can help.