WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

Because of its simple equipment, continuous operation, high production efficiency, and uniform green body performance, tape casting has become an important method for preparing the large and ultra-thin ceramic parts like ceramic substrates, and has been widely used in the electronic industry, energy industry, and other fields, such as the preparation of Al2O3, AlN circuit substrates, BaTiO3-based multilayer capacitors and ZrO2 solid fuel cells. In addition, the ceramic backplane of the mobile phone can also be prepared by tape casting process.

Because of its simple equipment, continuous operation, high production efficiency, and uniform green body performance, tape casting has become an important method for preparing the large and ultra-thin ceramic parts like ceramic substrates, and has been widely used in the electronic industry, energy industry, and other fields, such as the preparation of Al2O3, AlN circuit substrates, BaTiO3-based multilayer capacitors and ZrO2 solid fuel cells. In addition, the ceramic backplane of the mobile phone can also be prepared by tape casting process.

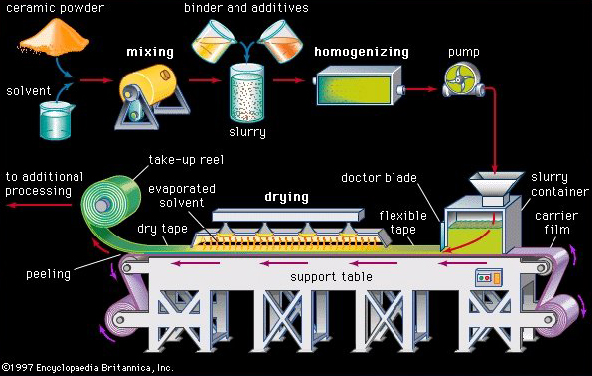

The specific process of tape casting molding is to fully mix ceramic raw materials and various additives (such as dispersants, plasticizers, binders, defoamers, etc.) in solvents, so that all materials, additives, and solvents are fully mixed to produce a stable and uniform slurry.

Then the slurry is poured into the hopper so that the slurry flows from the bottom of the hopper to the upper surface of the baseband, and the parameters such as the moving speed of the baseband and the height of the hopper are controlled, and the ceramic billet of the required thickness is formed on the baseband with the operation of the baseband. after the ceramic piece is dried, the mold can be removed, and then the follow-up procedure can be carried out.

The casting slurry is composed of binder, plasticizer, and solvent. Zirconia ceramic tape casting is suitable for making thin films with thickness below 0.05mm. This kind of thin-film is often used in small volume and large capacity electronic devices.

Tape casting is simple and stable processing, it can be operated continuously, it is convenient for automation and the production efficiency is high. But the binder content is high, so the shrinkage is high, up to 20%-21%.

The main advantage of tape casting is that it is suitable for forming large sheet ceramics or metal parts. It is almost impossible or difficult for this kind of parts to be formed by pressing or extrusion, but it is very easy to make green bodies of various sizes and shapes by casting forming, and the quality of green bodies can be guaranteed.

It is reported that a ceramic sheet with a thickness of 3μm has been formed internationally, and it has been studied that a sheet with a thickness of 12μm ~ 3mm can be formed on an ordinary tape casting machine.