WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

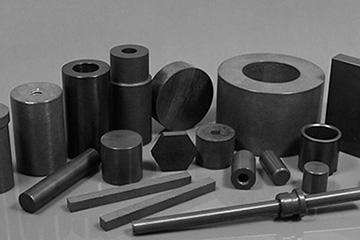

Ceramic Rods & Bars

Ceramic Tubes

Ceramic Sheets & Blocks

Ceramic Valves

Ceramic Rings & Bushings

Ceramic Pumps & Plungers

Ceramic Flanges

Ceramic Nozzles

Ceramic Pins & Needles

Ceramic Arms

Other Ceramic Parts

Silicon Nitride (Si3N4) shows us the greatest cross-sections of material properties across the technical ceramic groups, this makes it a structural ceramic with the best comprehensive properties, and able to provide specialist solutions for those harshest industrial working conditions on earth.

In recent years, silicon nitride ceramics have made great strides in a number of industrial applications, which allowed great flexibility and customization to create precisely the parts needed.

In general, the applications of silicon nitride ceramic parts include but are not limited to:

Parts subject to high stress, such as ball bearing, roller bearing, and automotive components

Parts subject to rapid temperature changes

Parts requiring high strength, even at high temperature

Parts requiring high-temperature resistance and high-load abilities

Parts requiring high resistant to abrasion and low friction

To achieve tighter tolerances and high smoothness, Mingrui Ceramic machinined / ground the fully sintered parts with diamond tools. Contact us for the available sizes and machining capabilities.