WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

Zirconia ceramics can obtain good hardness and toughness after quenching, which makes them play a better role in practical application.

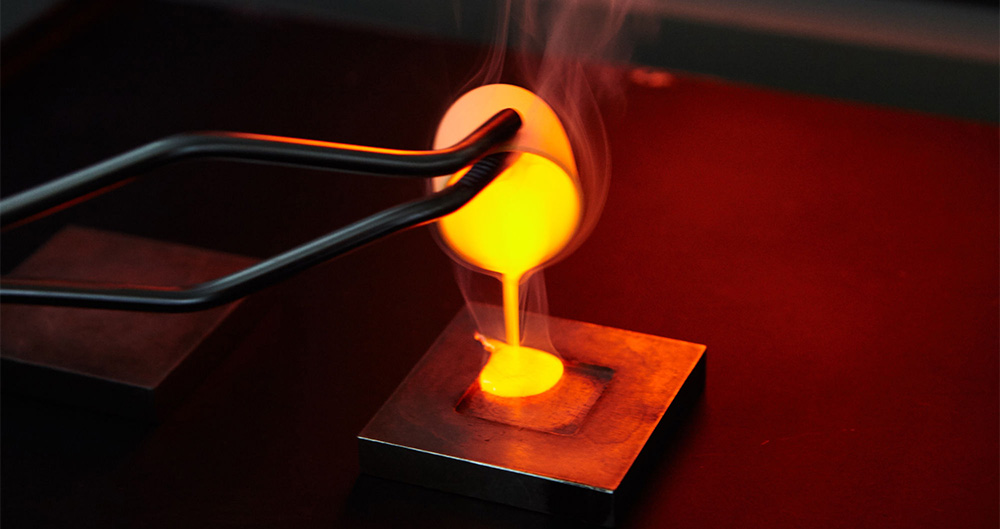

Zirconia ceramics can obtain good hardness and toughness after quenching, which makes them play a better role in practical application. Therefore, quenching is a necessary process to improve the properties of zirconia ceramics, and the specific reasons are as follows:

1. There is no need for overall heating, small deformation, and low consumption of the workpiece.

2. The heating speed of the zirconia ceramic structural parts is fast, and the oxidation and decarburization of the workpiece surface is light.

3. The surface hardened layer of the zirconia ceramic structural parts can be adjusted according to the need, so it is easy to control.

4. The martensite structural parts of the hardened layer is fine, and the hardness, strength, and toughness are higher.

5. After quenching, there is a large compressive internal stress on the surface of the workpiece, and the anti-fatigue breaking ability of the workpiece is higher.

Zirconia ceramic structural parts have a better performance after quenching, which can create higher economic value for enterprises and bring convenience for users.