WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

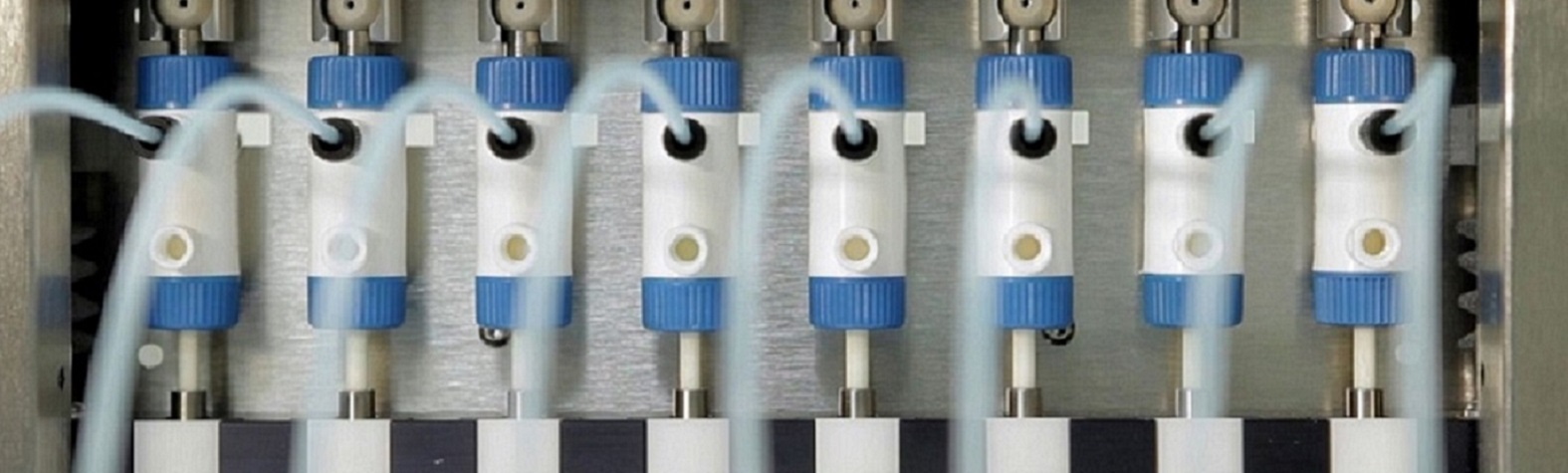

The dispensing process is used in the production of many industrial products, and ceramic dispensing valves are widely used due to their excellent performance. However, if you want to ensure the quality of the glue dispensing process, you must control the glue output of the ceramic dispensing valve so that the glue can be evenly applied to the corresponding position for better adhesion. Specifically, the skills to control ceramic dispensing valves include the following aspects.

The dispensing process is used in the production of many industrial products, and ceramic dispensing valves are widely used due to their excellent performance. However, if you want to ensure the quality of the glue dispensing process, you must control the glue output of the ceramic dispensing valve so that the glue can be evenly applied to the corresponding position for better adhesion. Specifically, the skills to control ceramic dispensing valves include the following aspects.

1. Calculate the amount of glue needed

Because the amount of glue required for different products is different, this is mainly determined by the volume of the dispensing position of the product, so the amount of glue should be calculated clearly and set up in advance.

Only by making such preparations can the glue output of the ceramic dispensing valve meet the requirements in the subsequent operation process, so that the production of the product can achieve the most perfect effect.

2. Set the glue time

In order to better control the amount of glue out of the ceramic dispensing valve, the glue-out time should be set. Because the glue out speed is constant, the longer the time, the more out the amount.

Therefore, it is also a very important factor to grasp the good glue time, so the time parameters should be adjusted and set in advance in order to achieve the best glue dispensing effect.

3. Liquid glue is controlled in a special way

Since the liquid glue will flow by itself, in order to avoid this situation from affecting the dispensing effect, thereby affecting the quality of the final product, we recommend using a pneumatic dispenser to deal with this situation.

Because the air pressure allows the dispenser to suck back the excess amount at any time, the part can be retracted before too much liquid glue flows, so as to more accurately control the amount of glue out of the ceramic dispensing valve to achieve better accuracy.

In addition, if the glue used is relatively viscous, it is recommended to use a screw valve or a dispenser with a heating function to increase the fluidity of the glue so that the amount of glue can be better controlled.

In a word, in most cases, it is necessary to choose an appropriate method to control the injection volume of the ceramic dispensing valve according to the nature of the glue, so that the correct response can be made and a better quality product can be obtained.