WELCOME TO CALL US +86 18122974730 Email:admin@mingruiceramic.com

Ceramic dispensing valves are widely used in dispensing machines due to their superior performance, so what are the advantages of using ceramic dispensing valves?

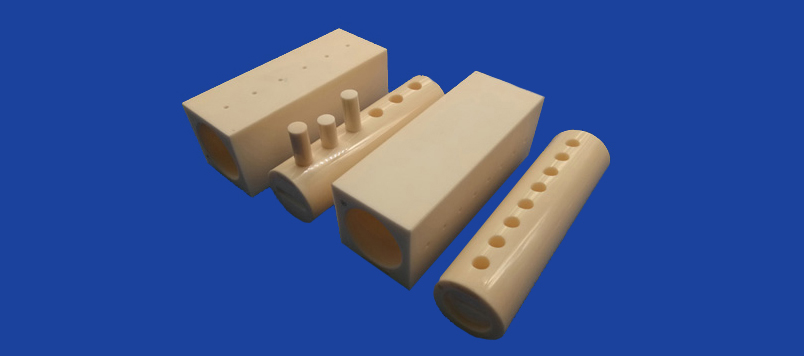

The ceramic dispensing valve is made up of a cylinder, a valve body and an outlet body which are connected up and down. The cylinder and the valve body are separated by a diaphragm to prevent the glue from invading into the air cavity. The valve in the outlet body is fixed on the piston rod. It has the function of opening and closing the glue.

The working principle of alumina ceramic dispensing valve: the ceramic dispensing valve compresses air into the glue bottle (syringe) and presses the glue into the feed tube connected to the piston chamber. When the piston is on the upstroke, the piston chamber is filled with glue, and when the piston pushes down the glue needle When the glue is pressed out from the needle nozzle. The amount of glue dropped is determined by the distance of the plunger, which can be adjusted manually or controlled in software.

Ceramic dispensing valves are widely used in dispensing machines due to their superior performance, so what are the advantages of using ceramic dispensing valves?

As professional technical ceramic manufacturer, we will introduce the four major advantages of ceramic dispensing valves.

1. Reduce the possibility of glue leakage and the smoothest liquid flow

The equipment generates the least back pressure when in use, and the ceramic dispensing valve controls the pressure to ensure stable dispensing, and the ceramic dispensing valve is resistant to high temperature and corrosion, and will not block the flow of glue, and the ceramic dispensing valve can be perfect solve the problem of rubber valve leakage.

2. Ceramic dispensing valve can solve the problem of too slow flow rate

The flow rate of the dispensing valve is too slow, which is also caused by the material of the metal dispensing valve itself. If the metal temperature is too high, when the liquid flows through, agglomeration will occur, which will form a blockage, and the flow rate will be correspondingly slower, resulting in inconsistent glue size.

The ceramic dispensing valve made of alumina ceramic material can perfectly solve this problem. The alumina ceramic itself has the characteristics of wear resistance and high-temperature resistance, which can ensure the normal flow of liquid even at high temperatures.

3. Alumina ceramic dispensing valve can ensure that the liquid does not dry up in the valve

This situation is mainly due to excessive moisture or repeated use of instant glue. The ceramic dispensing valve will not cause the temperature of the valve body to become cold due to the use environment. Therefore, the alumina ceramic dispensing valve can ensure a constant temperature state, and the liquid is When flowing through the valve body, it will not dry up and ensure the normal flow of liquid.

4. It can avoid the dripping problem of the dispensing valve

Traditional dispensing valves often have dripping and leakage, which is caused by the small diameter of the needle used. The metal dispensing valve is not resistant to high temperature, it is easy to stick colloidal liquid, and even affects the bubble discharge action. The alumina ceramic dispensing valve can perfectly solve the problem of glue leakage in the valve.